Let's Start at the Beginning

The other day I posted a picture of the remodel I’m doing to my lathe room. Today I will show the whole system from start to finish.

Above is a Grizzly GO442 cyclone dust collector with 2 cartridge after filters. Below it is a 4’ plywood cube with a sealed hinged door. It holds 64 cubic feet of wood dust, The cyclone came with a 40 gallon steel drum. It is on casters. The door has a plexiglass “window” so I can see when the cube is full. To empty it I pick it up with the tractor forks, open the door and shake, shake, shake. One leg of the ductwork goes to 2 band saws and a table saw. The other leg we will follow below.

The 8” duct runs through the “big” shop picking up the stroke sander, drum sander, 8” jointer, 16” jointer, 20” planer and table saw before it arrives here at the sliding compound miter saw. From there the duct goes through the wall into the attic of the “old” shop and down through the ceiling. You can see it poking through the ceiling in the next picture,

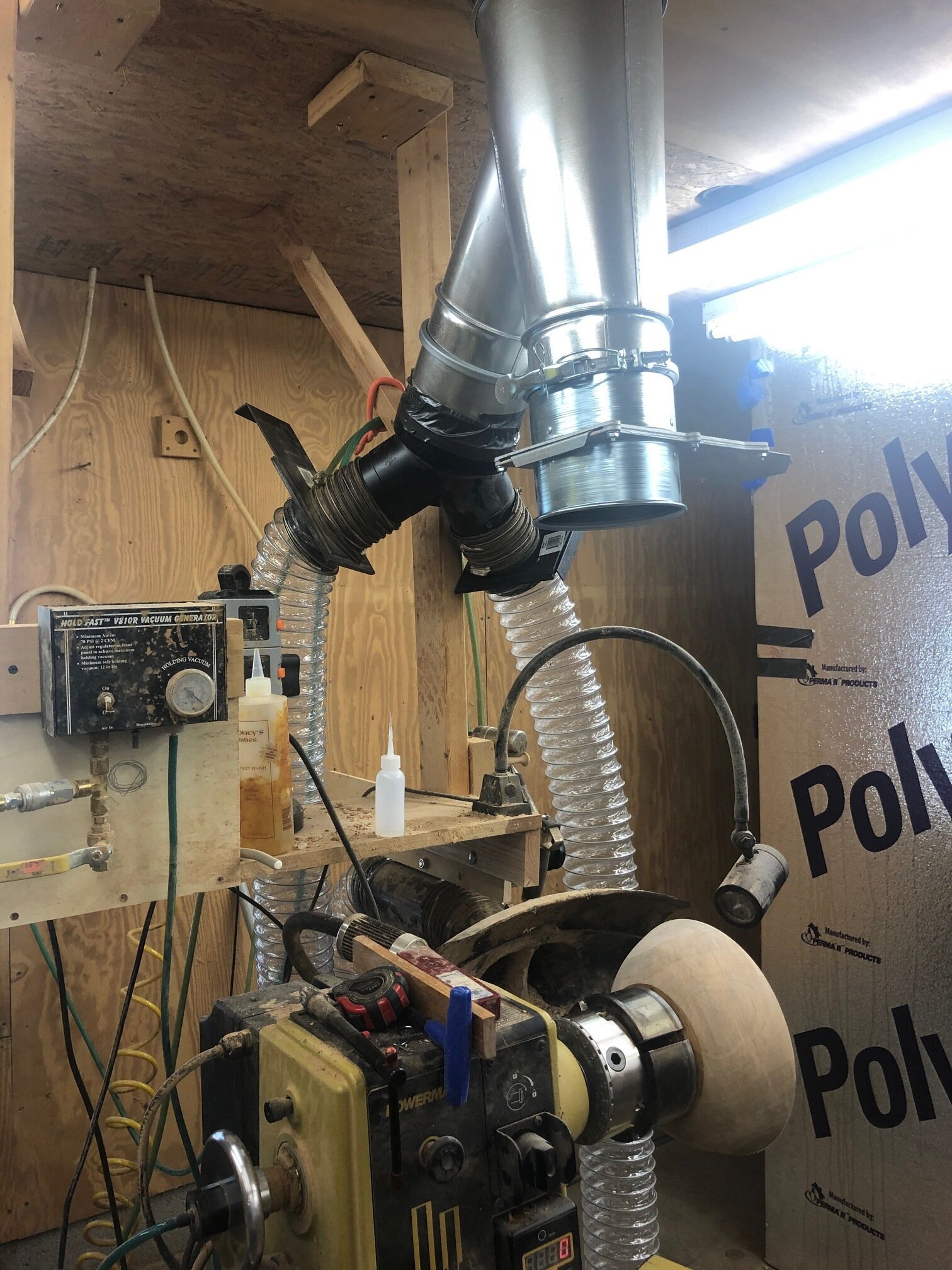

I have not made the hood for the duct above the bowl yet but it’s coming. In the background, where the foam board ends is the opening for the air cleaner pictured below. Air is drawn through the room to the air cleaner to get the very fine dust particles that escape the hoods. The air cleaner has fiberglass envelope bags behind 2 big HVAC type pleated filters. Those replaceable pleated filters are expensive so the hoods near the bowl need to be very efficient, reducing the amount of dust that is picked up by the air filter. I bought the air filters used. They were originally in a Nascar race team’s shop.

And finally the vacuum hose for clean up pictured below.

I actually learned this trick from the vacuum truck guys that clean up spills of dust at industrial sites. The handle protrudes past the hose opening to keep the hose from suctioning stuck to the floor. The handle attachment method is precisely formed, very sticky duct tape.